The forgotten relics of our past often carry stories that are far richer than we remember. One such humble yet essential tool was the vintage ice pick. Before refrigerators gave us the luxury of crushed ice on demand, this simple device was a kitchen necessity and even a symbol of hospitality in some homes. Let’s take a deeper look at its fascinating history and the role it once played in everyday life.

The Golden Age Of Ice Delivery And Why Everyone Needed One Of These

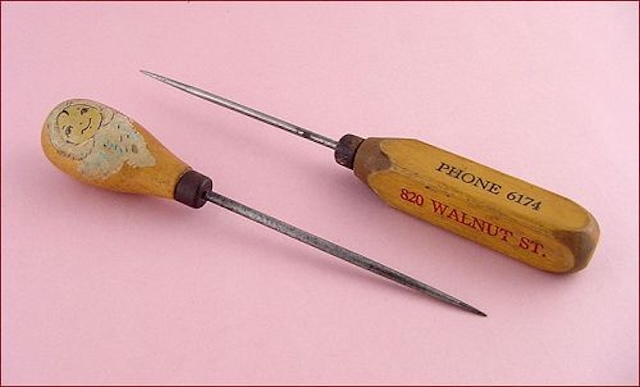

Imagine a time when ice wasn’t something you simply got from your freezer. In the early to mid-20th century, especially during the 1920s to 1950s, ice was delivered to homes by the “iceman” and stored in iceboxes. These heavy blocks of ice had to be chipped down into usable chunks, and that’s where the vintage ice pick came into play. Its sharp steel tip and sturdy wooden handle made it perfect for piercing and breaking ice with control and precision.

In many households, this tool sat proudly next to the icebox, often getting more use than many utensils in the kitchen. People used it to chip ice for lemonade, cocktails, or simply to cool down drinking water on a hot summer day.

Video

Check out this sleek and durable AllStainless Ice Pick in action—this video shows why it’s a must-have tool for bartenders, outdoor lovers, and anyone who appreciates quality gear!

A Symbol Of Hospitality At Dinner Tables And Social Gatherings

The vintage ice pick wasn’t just utilitarian; it became associated with social grace. Having fresh chipped ice was a marker of thoughtful hosting. When guests came over, offering them a glass with freshly chipped ice rather than lukewarm water was a sign of care. Bartenders, both professional and amateur, used ice picks to carve the perfect ice cube for classic drinks like an Old Fashioned or Mint Julep.

In fancier homes, some ice picks were even customized or monogrammed, becoming heirlooms passed down through generations.

Industrial Designs And Their Evolution Over The Years

The design of the vintage ice pick may seem simple, but there were variations that made them unique. Some had protective caps to cover the point when not in use. Others featured ergonomic handles or reinforced steel cores. Companies like Silex, Swing-A-Way, and even Coca-Cola produced branded picks as promotional items during the mid-century era.

Some ice picks came bundled with wooden boxes or leather sheaths, while others had built-in mechanisms for grip or safety. These tools were often as attractive as they were practical.

Moments In Pop Culture Where The Ice Pick Took The Spotlight

While many of us think of the vintage ice pick as a kitchen tool, it found its way into Hollywood too. Perhaps most (in)famously, it was featured in thrillers like Basic Instinct, though in quite a different light. Despite this, its on-screen appearances reflect just how recognizable and commonplace it once was.

Aside from fictional drama, ice picks also featured in documentaries and educational clips about 20th-century domestic life, underlining their ubiquity in mid-century American homes.

How This Tool Transitioned Into A Collector’s Favorite Today

With the rise of electric refrigerators and automated ice makers, the vintage ice pick fell out of daily use. But it never truly disappeared. Instead, it found a second life among collectors, vintage enthusiasts, and artisans.

Today, you can find old ice picks in antique shops, flea markets, and even repurposed in modern bars where mixologists appreciate the art of hand-chipped ice. Their nostalgia, durability, and beauty have made them decorative items as well.

Some people even use them for crafts, leatherwork, or as rustic tools in woodworking studios. The simplicity of their design allows them to be versatile long after their original purpose faded.

Closing Thoughts: A Humble Tool With A Legacy Of Connection

Though it may look like a primitive object by today’s standards, the vintage ice pick is anything but forgettable. It reminds us of an era where things were done by hand, where effort met intention, and where hosting someone with a cold drink meant chipping away a piece of ice yourself.

Its wooden handle still tells stories of busy summer afternoons, Sunday gatherings, and the clang of steel on ice echoing through warm kitchens. It wasn’t just a tool; it was a small but mighty part of daily ritual and memory.

So next time you see one in an old drawer or at a thrift shop, hold it for a moment. You’re not just holding metal and wood—you’re holding a piece of lived history.

Video

Watch the satisfying transformation in this hand tool restoration video as a vintage ice pick is brought back to life—rust to shine, it’s craftsmanship at its finest!

Have You Ever Used One?

Do you remember your parents or grandparents using an ice pick like this? Share your memories in the comments, or tell us about any vintage tools you still have tucked away. We’d love to hear your stories!