In every corner garage, farm outbuilding, and factory bench of yesteryear stood the vintage lever-action oil can, its slender spout poised like a surgeon’s scalpel. Generations of mechanics, machinists, and home inventors reached for that pump-handle – squeezing precise gushes of golden lubricant into gears, hinges, and pulleys. It wasn’t just a tool; it was a promise that squeaks would fade and metal would sing again. Today, we’ll journey through its origins, its everyday heroics, and why its hiss still echoes in our collective memory.

Humble Beginnings: How the Lever-Action Can Revolutionized Lubrication

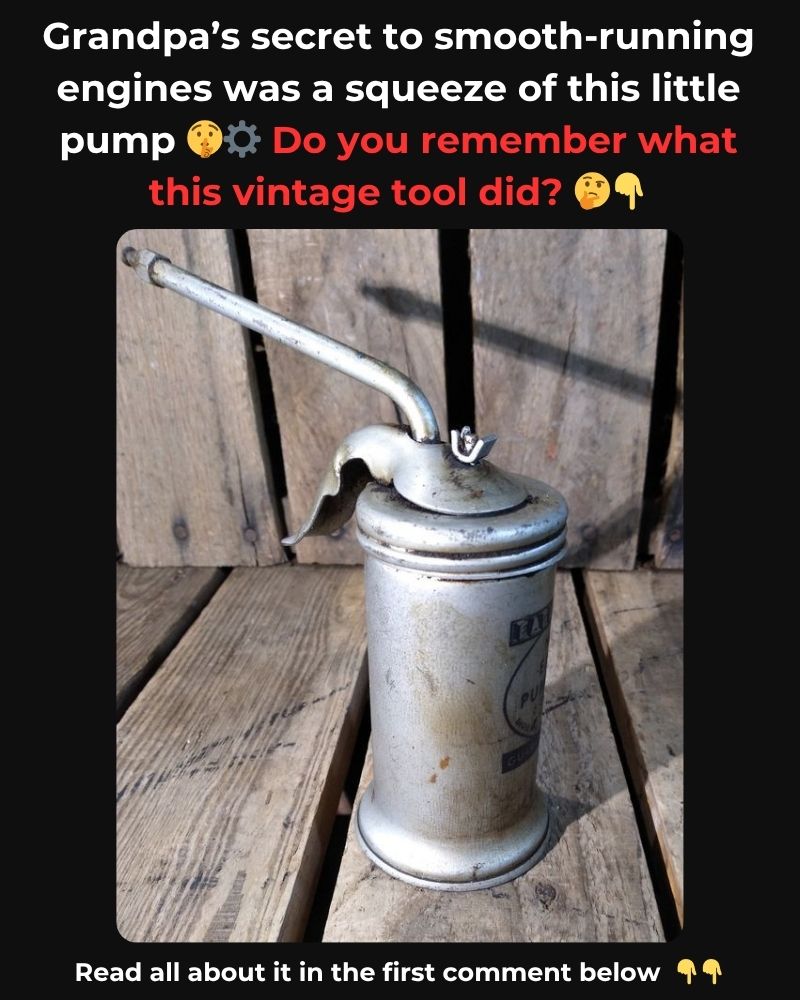

At the turn of the 20th century, factories roared to life with assembly lines and mechanized presses. Early oilers—simple dropper bottles or rags smeared with grease—were inefficient and messy. Inventors responded with the lever-action oil can: a sealed reservoir topped by a pump mechanism that delivered pinpointed squirts of oil under slight hand pressure. Patents filed around 1905 bragged of “no-leak” seals and “easy one-handed use.” Within a decade, every machinist and maintenance crew considered the vintage lever-action oil can indispensable—transforming lubrication from a groady chore into a swift, satisfying ritual.

Video

Watch Adam Savage bring vintage oil cans back to life in this satisfying restoration video—packed with history, craftsmanship, and a touch of nostalgic magic!

Engineering Elegance: Anatomy of the Vintage Lever-Action Oil Can

Though each maker added its flourish, classic oil cans share key design features:

Sealed Reservoir

Usually made of pressed tin or brass, these cylindrical bodies held up to a cup of light machine oil. Tight lids prevented drips and contamination.

Lever and Piston Mechanism

A spring-loaded piston inside the pump chamber created suction on release; squeezing the external lever forced oil through the channel into the spout. This simple pump action allowed precise control—no flooding, no fuss.

Swivel or Fixed Spout

Narrow metal tubes ranged from fixed straight nozzles to flexible, jointed spouts that bent into awkward angles—ideal for reaching deep bear- ing housings or the back of a cast-iron vise.

Ergonomic Handle and Thumb Rest

Some models sported a knurled thumb rest atop the lever for extra grip. Others featured contoured side grips, ensuring oily hands never slipped during operation.

Drip-Catch Lip

The base sometimes included a flared lip, catching any stray dribbles and keeping benches clean.

This marriage of reservoir and pump, spout and seal, made the vintage lever-action oil can a masterpiece of functional design—compact, robust, and intuitive.

Everyday Salvation: Tales of Squeaky Hinges and Rusty Gears

Across countless homes and shops, oil cans performed silent acts of heroism:

The Gate That Wouldn’t Swing

On a Midwest farmstead, a sagging gate hinge squealed under every open. A neighbor with a battered oil can arrived, bent the spout through chicken-wire fencing, and pumped two soft jabs of oil—restoring quiet even before sundown.

The Factory Press Game

In a 1920s metal shop, night shifts depended on a single oiler man. His well-worn can perched next to the control panel, ready to rescue jammed presses and keep production humming. Stories say he knew each machine’s groan and answered with a drip of lubricant before any failure.

Typewriters and Sewing Machines

Steno pools and tailor studios relied on miniaturized spouts to oil the carriage rails of Underwoods and Singer sewing machines—ensuring each keystroke and stitch remained effortless.

Home Inventor’s Best Friend

Amateur radio hobbyists, clockmakers, and DIY tinkerers tucked oil cans into toolboxes, granting mechanical life to antique wind-up toys, motors, and lawn-mower blades alike.

Each squeeze of the lever felt like a small miracle—turning screech into silence, resistance into rotation, neglect into nurturing.

Industrial Icons and Handy Heroes: Notable Moments in Oil-Can Lore

The oil can even sneaked into legends and industry firsts:

Edison’s Workshops

Thomas Edison’s Menlo Park labs reportedly used custom brass cans with ultra-fine spouts for lubricating intricate phonograph mechanisms—proof that even the greatest inventors needed humble lubrication.

WWII Arsenal Maintenance

Field armories depended on pocket-sized lever-actionters to oil rifles, tanks, and anti-aircraft guns under duress. Anecdotes credit these cans with reducing jams in critical moments.

The “Flying Can” Prank

In mid-century machine shops, trainees dared each other to spin fully loaded cans at high speed on polished benches—seeing who could keep theirs sealed the longest without bursting or splattering oil everywhere.

Display in Design Museums

The Museum of Modern Art once featured early 1900s oil cans in an exhibition on industrial design, highlighting their elegant simplicity alongside iconic Bauhaus furniture and lighting.

Through these episodes, the oil can transcended its role as a mere tool to become a symbol of industrial ingenuity.

Restoration Revelries: Bringing Old Oil Cans Back to Glory

Though modern oilers have largely switched to plastic squeeze bottles or spray cans, collectors and craftsmen cherish vintage models:

Cleaning and De-Rusting

Enthusiasts soak reservoirs in mild acids, scrub out sediment, and polish brass surfaces to a warm glow—revealing faint maker’s stamps once hidden under grime.

Replacement Parts

New rubber gaskets, O-rings, and small springs revive long-dead pistons, making old cans pump like new. Hobbyists swap nozzles from broken units, assembling hybrid masterpieces.

Display and Use

A restored lever-action can looks regal on a workbench, ready for occasional use. Modern small-batch toolmakers even craft new spouts to fit vintage bodies—honoring the original while adapting to today’s oils.

This restoration movement underscores a shared respect for tools shaped by hand and purpose.

Lessons in Precision and Care: What a Simple Can Teaches Us Today

Reflecting on the vintage lever-action oil can reveals timeless insights:

Value of Specialized Tools

A dedicated oiler outperforms makeshift greasers. Investing in purpose-built gear yields better results and fewer frustrations.

Mindful Maintenance

Regular lubrication prevents breakdowns, whether on machinery or in relationships. Small acts of care avert larger failures.

Sustainability in Durability

Brass and steel cans outlast countless plastic disposables, reminding us that lasting craftsmanship aligns with ecological responsibility.

Joy of Tactile Ritual

The firm click of the lever, the hiss of oil pressurized through a spout—these sensory details anchor us in the moment, turning upkeep into ritual.

In a world of touchscreen commands, the humble oiler invites us back to hands-on practice and slow, deliberate action.

Video

Watch the transformation unfold in this antique oil can restoration—rust, grime, and age give way to shine and timeless charm in a truly satisfying revival!

Conclusion: Honoring the Quiet Workhorse of Workshops Past

Though spray cans and oil pens now dominate, the vintage lever-action oil can remains a testament to ingenuity, economy, and care. Each carefully crafted model—whether battered and dented or freshly restored—whispers of hands that built factories, fields, and family heirlooms alike.

So next time you face a squeak or a stiff joint, imagine sitting at a wooden bench, grasping a cool metal body, and feeling the gentle satisfaction of a measured squeeze. In celebrating this unassuming marvel, we honor the simple mechanics that quietly made our machines—and our work—sing.