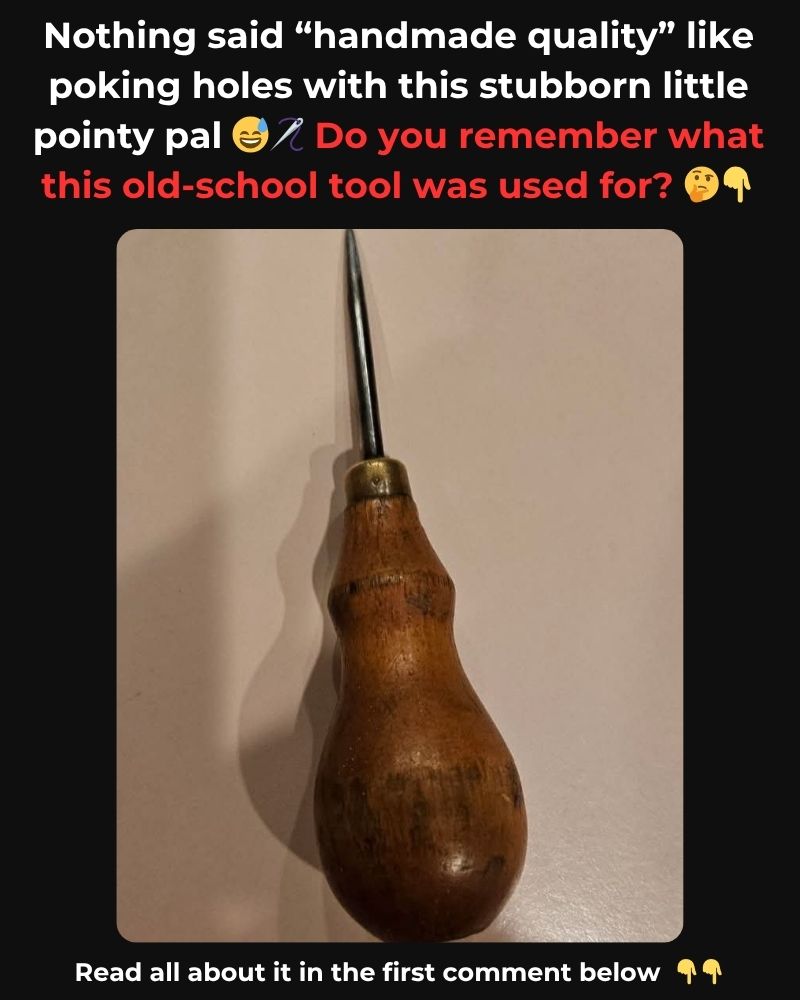

In every leatherworker’s bench from cobblers’ stalls to frontier saddleries stood the humble traditional leather punch awl, its slender steel tip and turned wooden handle glinting beneath lamp light. With a steady hand, artisans of old used it to pierce perfect holes in thick hides—setting the stage for sturdy boots, bridles, and belts that carried us across continents. Far more than a pointy implement, this awl was a gateway to creativity, precision, and enduring style. Join us as we trace its journey through history, craft, and culture.

From Cave to Cobblestone: The Ancient Roots of the Leather Awl

Long before factories and fashion houses, our ancestors recognized leather’s unique strength and versatility. Stone-age awls—sharpened flints affixed to bone handles—punched animal skins to stitch them into garments. As metalworking spread in the Bronze and Iron Ages, bronze and iron awls appeared in craftspeople’s toolkits across Mesopotamia and Europe. By medieval times, the leather punch awl evolved into a precision instrument, enabling guild-trained shoemakers and harness-makers to produce durable goods for knights and pilgrims. Its design became so standardized that every village cobbler carried a variant in his leather pouch—a testament to the awl’s deep roots in human ingenuity.

Video

Learn how to master the Speedy Stitcher sewing awl in this easy-to-follow video—perfect for beginners and DIY enthusiasts looking to tackle leather, canvas, and heavy-duty repairs with confidence!

Crafting Holes with Purpose: How the Traditional Leather Punch Awl Works

Though deceptively simple, the traditional leather punch awl combines thoughtful ergonomics with reliable performance:

Tapered Hardened Steel Shaft

The awl’s point tapers gently, allowing craftsmen to start a small pilot hole and then enlarge it by twisting—precisely sizing each stitch hole to thread thickness or buckle tongue.

Turned Wooden Handle

Typically crafted from beech or maple, the handle’s bulbous base and narrow neck permit a secure grip: palm support for pushing, thumb–forefinger control for twisting.

Brass Ferrule Reinforcement

A metal ferrule at the junction of handle and shaft prevents wood from splitting under repeated leverage, ensuring decades of faithful service.

Protective Sheath (Optional)

Many awls slipped into leather sleeves or stitched tool rolls, safeguarding both the point and the worker’s fingers between uses.

These features made the awl an essential “first tool” in any leather project—guaranteeing neat stitch lines, uniform thread tension, and professional finish.

Stories from the Bench: Cobblers, Saddlers, and Soldiers Alike

Across time and geography, the leather punch awl inspired tales of skill and adventure:

Frontier Cobblers in the American West

In 19th-century gold-rush towns, itinerant cobblers set up shop under canvas awnings. With one hand steadying a postage-stamp stool and the other wielding an awl, they repaired boots fast enough to keep miners on their feet—and the frontier economy moving.

World War I Trench Gear Repairs

Soldiers in the mud of Flanders relied on portable sewing kits with miniature awls to fix torn boot uppers and strapped gas-mask bags. A well-placed punch meant the difference between blistered feet and mobility on the line.

Victorian Fashion Houses

In London’s West End, bespoke leatherworkers used ultra-fine awls to hand-sew Swift leather handbags and portrait cases. Each hole had to be invisible—punched from the inside out—and the awl delivered that invisibility with surgical precision.

Local Artisan Workshops of Today

Modern leather artisans use vintage awls to craft rugged tool rolls, hand-stitched journals, and artisanal footwear—whispering tales of heritage with every hole and thread.

Each of these narratives underscores the awl’s role as both practical implement and storyteller—connecting labor to lifestyle.

Leather Legends and Historical Milestones: When Awls Made Headlines

Even in broader history, the awl has left its mark:

Lewis and Clark Expedition (1804–1806)

Corps members repaired moccasins and portage packs with leather awls fashioned from trade-knife blades—enabling the transcontinental trek.

Industrial Revolution

Factories imported millions of horse-hide aprons; stitchers used standardized punch awls at workstations, ushering in mass-production of harnesses and upholstery.

Prohibition Speakeasies

Leather flasks carried bootleg spirits; secret compartments within violin-case doors were hand-stitched using awls—guarding illicit cargo with stealthy craft.

Space-Age Experimentation

In the early days of NASA, prototype spacesuit boots underwent field repairs using awls and heavy-duty waxed thread—a surprising nod to an ancient tool in futuristic settings.

These milestones reveal the awl’s surprising versatility—from conquering frontiers to aiding clandestine operations.

Revival and Reverence: Why Modern Makers Cherish Vintage Awls

Though multi-head punches and CNC machines dominate turnkey workshops, a renaissance of handcrafting has elevated the traditional leather punch awl:

Heirloom Toolmaking

Craftspeople hand-turn handles from reclaimed wood and forge shafts from high-carbon steel, paying homage to vintage designs while refining tolerances.

Tool-Sharpening Rituals

Artisans spend hours honing awl tips on oilstones and stropping pads—celebrating the tactile reward of a perfectly sharp point.

Educational Workshops

Leather-working schools integrate awl techniques—teaching beginners to appreciate the rhythmic push-and-twist motion and the satisfaction of pulling a flawless thread through freshly punched holes.

Collectors’ Cabinets

Antique tool enthusiasts display racks of pre-war awls, each tagged with maker’s marks and provenance—treasuring them as functional art.

Through these armed revivals, the awl transcends its utility to become an emblem of thoughtful craft.

Lessons in Patience and Precision: What This Simple Tool Teaches Us

Beyond leatherwork, the traditional leather punch awl offers broader life lessons:

Mindful Process

Each hole demands deliberate pressure and measured twist, reminding us that careful attention yields superior results.

Small Acts, Big Impact

A single row of uniform stitches strengthens entire assemblies—paralleling how small, consistent actions build lasting habits.

Respect for Materials

One learns to feel the hide’s grain and tension; overzealous force tears leather, just as overextension in life invites burnout.

Hand Over Machine

In an age of instant results, the awl invites us to slow down and value the human touch—the subtle wobble, the slight burr, the personal signature of craft.

These teachings resonate far beyond workbenches—anchoring us in patience, presence, and pride in process.

Video

Explore the versatility of this interchangeable awl set in action—watch how it makes leatherwork, crafting, and repairs easier with precision and ease!

Conclusion: Honoring the Quiet Power of a Point

Though the whine of laser cutters and hum of automated punches grow louder in modern workshops, the traditional leather punch awl endures. Its unassuming form—wood handle, brass ferrule, tapered steel spike—embodies centuries of ingenuity and quiet perseverance. Every hole it makes holds a story: of pioneers, of artisans, of everyday people mending boots or forging utility belts.

So the next time you marvel at a hand-stitched journal or slip on a pair of artisanal shoes, spare a thought for that simple awl. In celebrating its legacy, we celebrate the timeless joy of creating with our hands—one deliberate push and twist at a time.